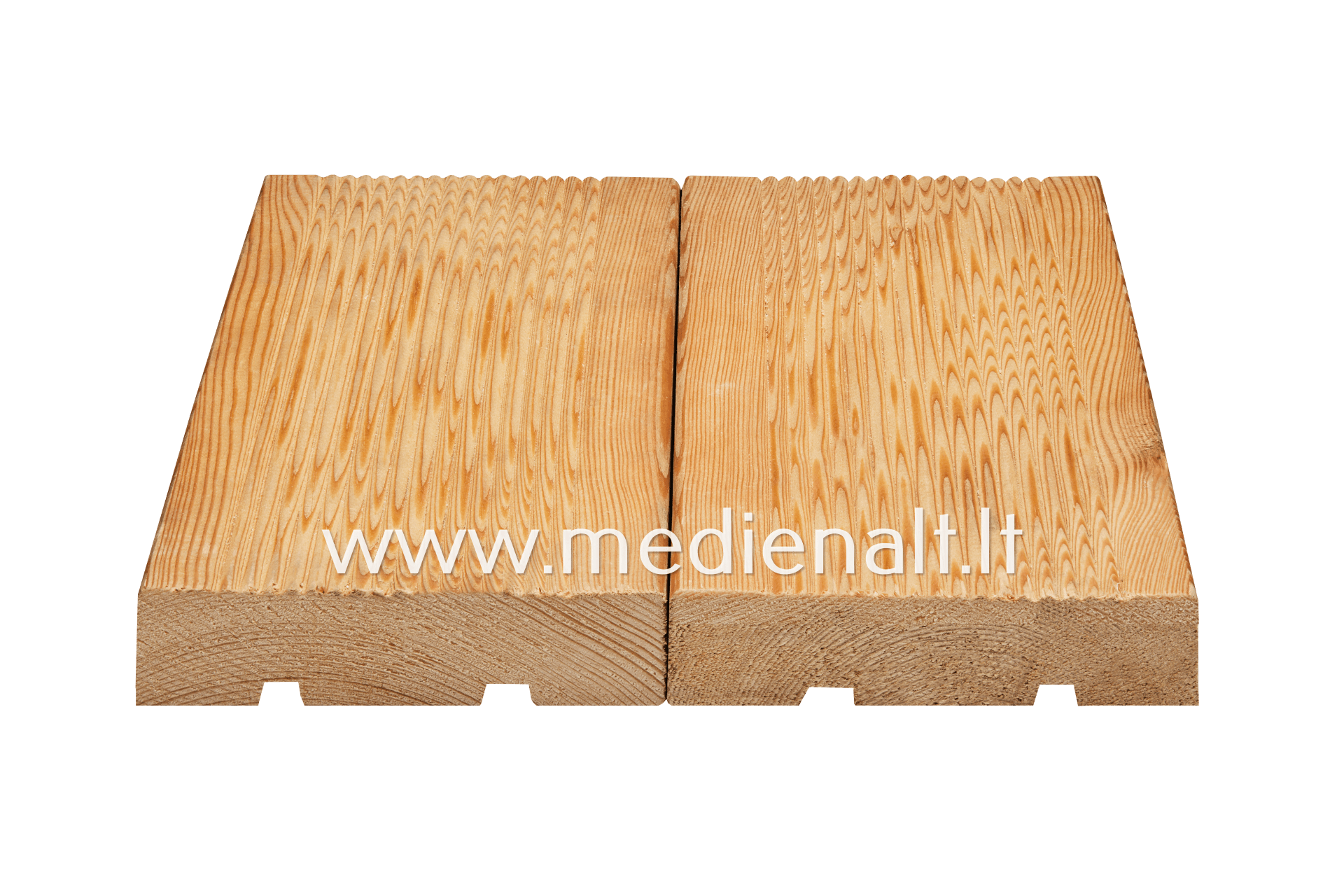

Wood calibration

Calibrated wood

| Height | 28 mm |

|---|---|

| Width | 45 mm |

| Length | 3000-6000 mm |

| Quality | AB or C24 |

| Height | 45 mm |

|---|---|

| Width | 45 / 70 / 95 / 120 / 145 / 195 / 220 / 245 mm |

| Length | 3000-6000 mm |

| Quality | AB or C24 |

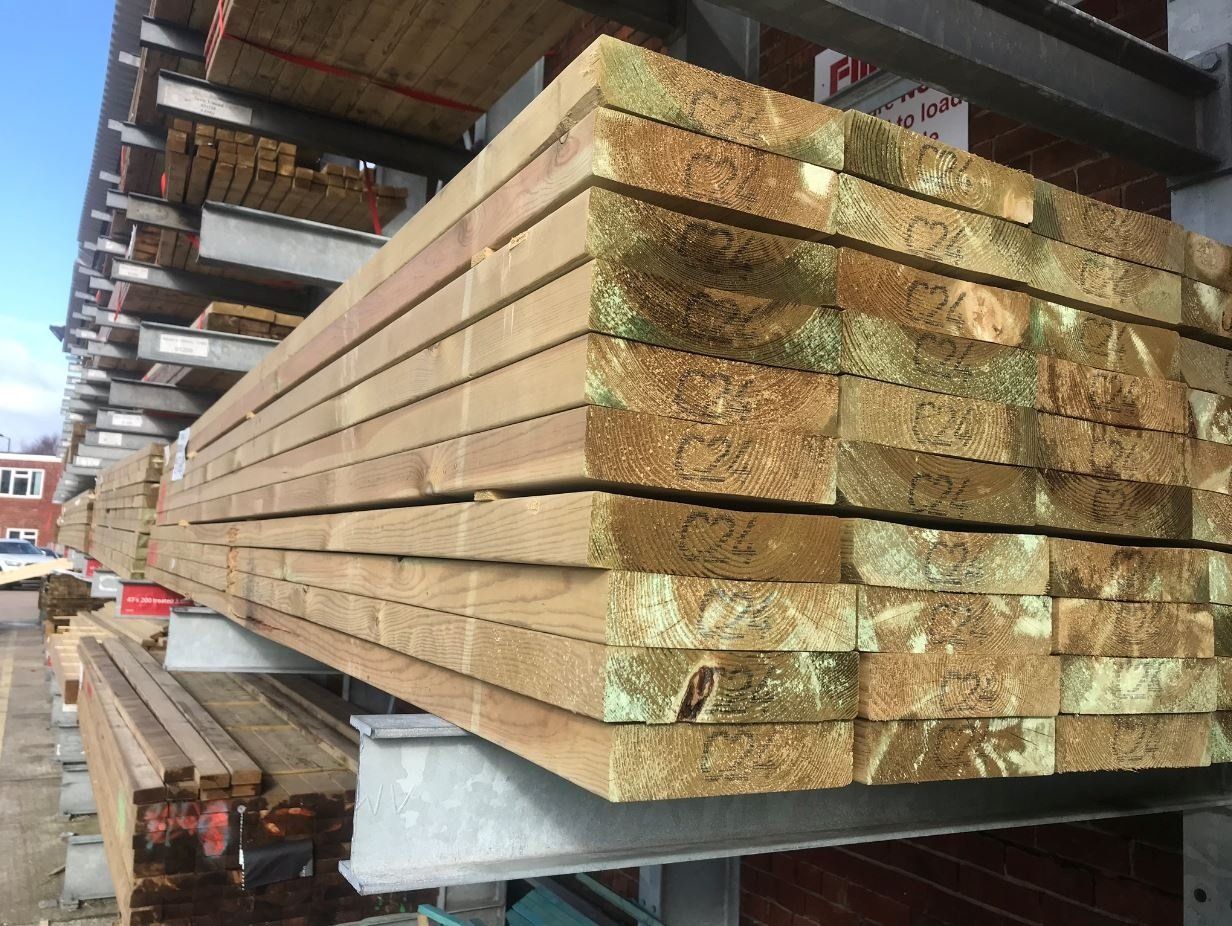

Calibration

Calibration – it is when each wood beam is evaluated according to its strength properties and marked with the letter "C" and number. The higher the number, the higher load can be undertaken by the wood (assessed in terms of resistance to bending, tension, pressure, as well as parameters such as elasticity and density). The two most common classes in Lithuania and the EU are C16 and C24.

Calibrated wood

Calibrated wood is used in load-bearing structures, where accurate calculation of loads is essential (e.g., rafters, struts, etc.), it is also used in areas where wooden structures form the basis of the structure and other elements are attached to it. In this case, the accuracy of the wood dimensions is very important, as it allows to lay the deck extremely smoothly without much effort and greatly facilitates the work (if, for example, OSB is attached to wooden elements). The above-mentioned properties are very relevant in the construction of frame, panel and modular houses.

Calibration

Qualitative sorting of wood can be visual strength grading and machining strength grading. Visual strength grading – it is when wood is sorted visually, where the number of branches, size, branch ratio is the most important. The sorter must be specially trained and licensed. Meanwhile, machine strength grading is more accurate. Mechanical strength sorting of wood can be performed by the company only with the appropriate certificate. Each board must be marked with: the type of wood, the strength grading standard, the manufacturer's identification number and the certification company identification number. In addition, the European Union has developed a “CE” safety class for wood products.